For angle drilling and screwdriving around corners and in tight spaces.

Whether in the workshop, on the construction site or at home: The Festool App is your companion for smart working and perfect results.

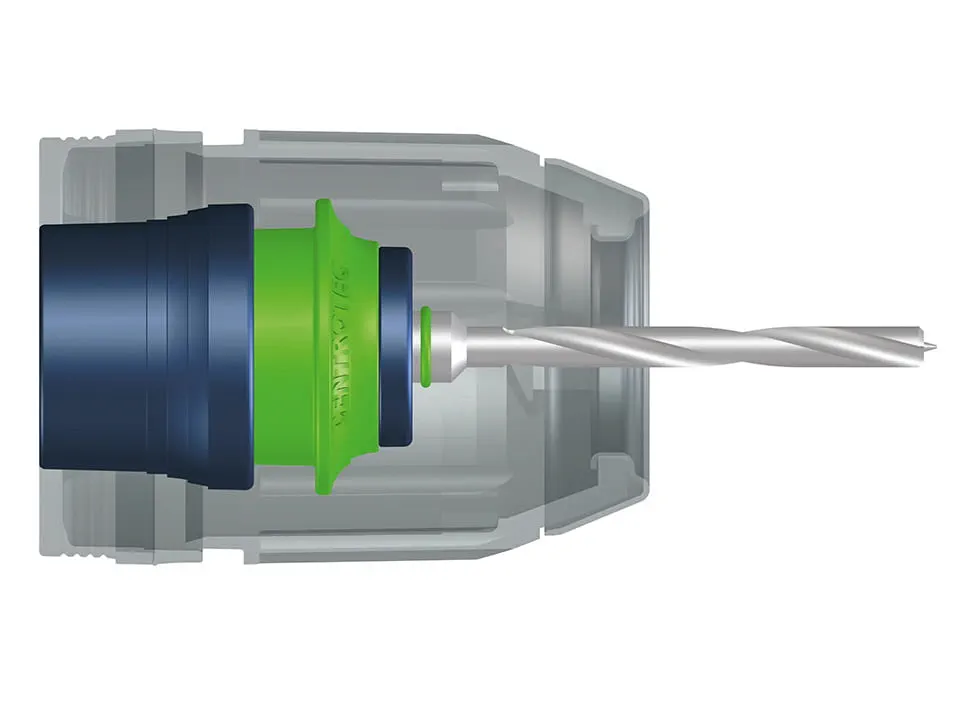

Our cordless drills and screwdrivers impress with their ideal weight distribution and ergonomics, well thought-out details and sensitivity in every application - from light assembly work to demanding timber construction. What makes our cordless screwdrivers special and your work more efficient? The extensive system accessories! Our FastFix attachments are real problem solvers and the CENTROTEC quick-change system saves you valuable time when changing applications.

Whether you need to screw close to the edge, work in tight spaces, series screw fastening with a defined screw depth or precise drilling with the drill attachment - the FastFix attachments are your problem solvers. They are compatible with the majority of Festool cordless screwdrivers* and are easy to couple, exchange and use without tools.

*For machine compatibility, see product detail page

If something should happen to your screwdriver in the course of hard everyday work, we will be happy to repair it - within the first 3 years of our all-inclusive warranty*, of course.

* All-inclusive warranty is valid for all Festool tools purchased from 6th March 2013 onwards and registered within 100 days of purchase. Visit www.festool.ie/warranty-terms-and-conditions.

Festool cordless screwdrivers are flexible all-rounders and work quickly, precisely and safely. With high speed and powerful torque, cordless screwdrivers drill or screw into wood, stone and even metal. You can also work in hard-to-reach places with precision and control. For long periods of time and without fatigue. This is because cordless screwdrivers are light, compact and perfectly balanced. The cordless screwdriver sits comfortably in the hand and the slim handles enable perfect handling. A cordless drill stands for flexibility, power and reliability and is therefore suitable for numerous applications: From light assembly work to demanding drilling and screwdriving applications in wood and metal.

With a Festool cordless drill, you can work faster, more comfortably and more safely.

Festool cordless drill drivers are professional tools for the highest demands. Festool offers cordless screwdrivers with battery voltages of 12 and 18 V. Each tool impresses with its lightweight and compact design. Balanced centres of gravity and slim handles enable perfect handling. Even when drilling and screwdriving overhead. Just as perfect: The EC-TEC brushless drive concept stands for exceptional power delivery and economical energy consumption at any speed. From screwdriving in large screws to drilling at 3800 rpm. The CENTROTEC quick-change system is a Drill chuck and Bit holder in one. Bits and attachments can be changed without tools. The FastFix attachments turn a Festool cordless screwdriver into an angle drill driver and angle screwdriver, an eccentric screwdriver and a depth limiting screwdriver in no time at all. And lithium-ion batteries with 12 and 18 volts provide power and endurance for more than 1000 screws per battery charge.

Festool cordless drills - even better in the system.

Festool cordless screwdrivers fit perfectly into the system. Our system accessories such as the quick-change system, Angle attachment, Eccentric attachment, Depth stop, Battery packs, Chargers, Bits and Drill bits for a wide range of applications make your work with a Festool cordless screwdriver even more efficient.

The following guide shows how beams can be connected by longitudinal joints as part of a renovation. Portable circular saws, cordless drills and eccentric sanders are used to do this. One of the longitudinal joints created by carpenters, the French scarf joint, is primarily used to partially replace damaged wood in old buildings or to extend wood.

The following guide shows you how to build you own deconstructible sawhorse with a dovetail joint. In addition to Festool machinery, a LignaTool routing template is used to make the milled holes.

You do not need to have a powerful router and accessories to cut a kitchen worktop to size at the corner. You can use a circular saw to mitre-cut worktops and connect them at various angles, ensuring that the decors on the panels match up exactly. This application example also covers the subsequent gluing and other post-processing steps.