Dog Kennel

Required materials

- Position 1*: 1x; Underside length: 966; Width: 656; Thickness: 4; Betoplan

- Position 2: 1x; Upper side; 900 x 590 x 4; Betoplan

- Position 3: 2x; Longitudinal strips 900 x 35 x 4; Spruce; Betoplan

- Position 4: 3x; Cross strips 520 x 35 x 20; Larch

- Position 5: 1x; Door step; 320 x 33 x 24; Larch

Front/Back wall

- Position 6: 2x; Exterior; 695 x 638 x 9; BFU 100 plywood

- Position 7: 2x; Interior 695 x 590 x 4; Betoplan

- Position 8: 4x; Side strips; approx. 590 x 35 x 20; Larch

- Position 9: 4x; Upper curved strips: approx. 350 x 35 x 20; Larch

- Position 10: 2x; Door side strips; 325 x 35 x 20; Larch

- Position 11: 2x; Door curve strips; approx. 210 x 35 x 20; Larch

Side walls

- Position 12: 2x; Exterior; 966 x 551 x 9; BFU 100 plywood

- Position 13: 2x; Interior; 948 x 551 x 4; Betoplan

- Position 14: 4 x longitudinal slats; 448 x 35 x 20; Larch

- Position 15: 6x; Cross strips; 481 x 35 x 20; Larch

Roof

- Position 16: 1x; Upper side; 990 x 760 x 4; BFU 100 plywood

- Position 17: 1x; Underside; 900 x 670 x 4; Betoplan

- Position 18: 3x; Roof beams; 635 x 140 x 18; Betoplan

- Position 19: 2x; Border strip; 900 x 35 x 30; Larch

Fittings

- Position 20: 4x; Corner strip, white; 590 x 25/25 x 2; Plastic

- Position 21: 4x; Side hinge, zinc plated

Support grate (Adapt measurements individually)

- Position 22: 4x; Girders; 1450 x 50 x 60; Larch

- Position 23: 8x; Battens, long; 1650 x 80 x 20; Larch

- Position 24: 7x; Battens, short; 650 x 80 x 20; Larch

* Position in drawing

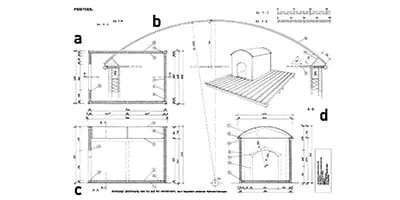

Construction drawing

Sketch and section, Scale 1:4

Roof detail, scale 1:1

a: Sketch

b: Roof detail

c: Section A-A

d: Section B-B

Additional tools:

- Flat drill

- Paintbrush

- Adhesive tape

- Cartridge applicator gun

- Hand saw

Process

-

Step 1

Cut the plywood sheets to size according to the specifications in the material list. If you would like to cut the individual panels yourself, it is easiest if you lay battens onto the ground as a base and use a plunge-cut saw with guide rail to do the cutting. We recommend constructing both side walls and the base panel to start.

-

Step 2

Cut the square timbers (positions 3, 4, 8, 14 and 15) to the required dimensions. If you only have other profile sizes, you can cut them to the correct size using a table saw. Mark the positions of the drill holes onto the square timbers before drilling. Screw together the individual frames for the base structure (4.5 x 80 mm screw size).

-

Step 3

Once the base structure is screwed together, insert the interior panels (positions 2, 7 and 13). Clamp the panels and drill the holes for the screws. Use SPAX screws (3.5 x 20 mm) to screw the panels to the base structure.

-

Step 4

When all of the interior panels and the base panel (position 1) have been screwed together, cut the Styrofoam insulation and place the sheets into the framework. Mark the positions of the base structure onto the exterior panels (positions 6 and 12). Use polyurethane adhesive to stick these to the rest of the wall. The individual parts of the wall should be braced with clamps.

-

Step 5

On the exterior panel that includes the front pediment, mark the centre points for the radius of the roof curve and the door. Build a simple compass from a strip of plywood. (At one end, drill a hole for a pencil to fit through. Measure the radius distance from the pencil tip and drill a hole with 3.5 mm diameter). Screw the compass to your panel using this hole at the marked centre point.

-

Step 6

Now you can draw the roof curve and then the curve for the entrance door. Use a jigsaw (curved saw blade) to cut out both curves and transfer the upper curve to the rear gable wall, then use the jigsaw to cut this too. Equally, the curve could be taken straight from the 1:1 scale drawing provided.

-

Step 7

Secure the two gable pieces together and sand the upper curves with coarse sandpaper. If you own a router with a copying ring, you can cut the gable wall curves instead. Mark the positions of the base structure onto the gable sides (positions 10 and 11).

-

Step 8

Here it is important that the battens extend far enough that later cuts on the round curve leave a closed upper edge. Use a protractor to measure the exact angle at which the strips must be cut. Set the angle on the mitre saw and cut the first side of the strip.

-

Step 9

Lay the cut strip onto the pre-marked position, mark the correct length and cut.

-

Step 10

Glue the strips piece by piece onto the gable panel. Follow the same process to glue the strips onto the front gable panel. Adjust the strips to fit the door and glue these on. The next step is to fit and adjust the Styrofoam sheet and the interior panels.

-

Step 11

Once both of the gable walls are completely constructed, use a jigsaw to cut the interior panels and the base structure along the curve. Place the gable sides onto the roof beams (position 18) of the roof structure and transfer across the upper curve. Use the jigsaw to cut the roof beams.

-

Step 12

In order to obtain a precise cut edge, change the pendulum stroke setting on the jigsaw to 1. Use a table saw to cut the roof end strips at an angle lengthways. For long cuts in solid wood, it is strictly necessary to use a coarse saw blade. Use the table saw to cut the strips to the correct length.

-

Step 13

Mark the width of the end strips onto the roof beams and cut the corners with the table saw. Mark the position of the connecting holes for the end strips and the ribs and drill the holes (dia. 4 mm). Screw the beams and the end strips together. Glue the roof beams and the roof exterior panels together.

-

Step 14

It is important to mark on the roof overhang now in order to facilitate positioning at a later stage. Again, we are using polyurethane adhesive. In this step of the process, you will need two people working together. We also advise that you have a dry run (without glue) to play around with the fit. Put glue onto the roof beams and fix the panel on one of the outer edges.

-

Step 15

Push down on the base structure to roll it over the panel and fix with clamps, first in the middle, then at the second end strip. Use as many clamps as necessary to achieve the required result. If you can still see gaps once everything is dry, seal the inside of the roof with silicone.

-

Step 16

Mark the position of the side hinges on the interior panels of the roof (position 17) and use the jigsaw to cut out correctly sized recesses for them to sit in. Screw the interior panels to the roof. Drill the connecting holes (dia. 4.5 mm) between the individual walls and then screw the kennel together.

-

Step 17

Place the roof onto the kennel and line it up correctly, then mark the position of the hinges. Use a flat drill to mark the bottom part of the hinge onto the outside of the wall. Take the roof away and screw on the hinge. Now, assemble the entire kennel and sand all edges and angles. Dismantle the kennel again and use an eccentric sander to sand all of the external surfaces.

-

Step 18

Final touch: P 180 sandpaper. If you wish, you can now paint the surfaces with waterproof glaze or varnish. Make sure you follow the processing guidelines from the manufacturer. Use a precision saw to cut the plastic corner pieces that can be permanently fixed to the kennel using polyurethane adhesive (Pattex X‑PERT). Use adhesive tape to hold it in place. Mask the roof front edge and paint the edge white.