Base and intermediate sanding: Sanding off doors coated full-surface with water-based paint

Description

Environmental and consumer protection is also an important goal of the European Community, and the European VOC directive (VOC = Volatile Organic Compounds) requires a significant reduction in the use of volatile solvents in paints and varnishes. This kind of far-reaching change to the materials used also results in changes to the properties of paints and varnishes. This affects not only the application and resistance properties of the coatings, but also the subsurface preparation required.

Due to their composition, systems that were previously conventionally used (e.g. alkyd resin varnish) exhibit better filling properties than paints and varnishes with reduced or no solvent content. What this means for users is that finer abrasive grain sizes must also be used for preparing surfaces for painting or varnishing (base sanding, filler sanding and intermediate sanding), as sanding marks can become more or less visible in the final product depending on the gloss and colour of the coating material. In addition, modern water-based paint systems clog up abrasives more heavily than older solvent-based paint systems.

Festool has designed a new generation of abrasives specifically for these paints – Festool GRANAT, specially designed for VOC paint systems. These abrasives can be used, for example, to renovate room doors or sand off door frames.

The following guide describes how the user can maintain the familiar level of quality in the final product, using the example of "Repairing and sanding off doors with water-based paint".

Tools/accessories

Alternative tools

Tip: A protection pad must be used when using an abrasive net.

Procedure

-

For applications such as sanding a door frame or refurbishing room doors, the following sanding steps must be followed (please also refer to the technical data sheet provided by your paint manufacturer):

- Sanding off the old paint from the wooden door (if required due to the coating/the condition of the doors)

- Applying filler/primer to the surfaces

- Intermediate sanding of filler/undercoat

- Applying repair compounds (if required)

- Intermediate coating

- Intermediate sanding

- Final coating

-

Sanding off old paint from the room doors:

- Connect the ROTEX geared eccentric sander to a mobile dust extractor.

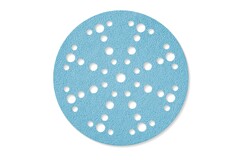

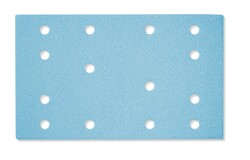

- Affix GRANAT P80 sandpaper (or coarser if required) to the sanding pad.

- Set the ROTEX to coarse sanding (rotary motion).

-

Switch on the tool and guide it evenly over the doors until the old paint layer has been sanded off.

Switch the tool to fine sanding and sand off the surface using GRANAT P120.

-

An orbital sander or linear sander is used in the rebate area of the doors.

-

Once filler/undercoat has been applied to the surfaces in accordance with the technical data sheet provided by your paint manufacturer, the first intermediate sanding required for renovating the front door takes place:

Intermediate sanding of the filler/undercoat:- The adhesion properties of the final coating and the smoothing away of spray, roller or brush patterns produced during the paint application process are both very important aspects of the intermediate sanding process for doors.

- Connect the eccentric sander to a mobile dust extractor.

- Affix GRANAT P240 abrasive paper to the sanding pad on the eccentric sander.

- Even distribution of the guide control black powder across the painted surface.

-

Once the guide control black powder is no longer visible, sanding of the surface is complete. Switch on the tool and guide it evenly over the surface until no more guide control black powder is visible.

-

If the abrasive becomes clogged during work, the speed of the tool is reduced. This clogging is caused as a result of the paint heating up and sticking to the abrasive.

-

Deeper holes or points of damage (that cannot be levelled off without sanding through the filler) are filled with putty, stripped away and re-sanded once dry using the eccentric sander and GRANAT P240.

-

Once the intermediate coating has dried completely and can be sanded, carry out intermediate sanding:

Different methods are possible depending on the intended surface structure.

In the event of visible spray, roller or brush patterns (also known as orange peel), follow these steps:- Connect the eccentric sander to a mobile dust extractor.

- Affix GRANAT P320 sandpaper to the sanding pad on the eccentric sander.

- Switch on the tool and guide it evenly over the doors until the spray, roller or brush patterns have been levelled off.

-

To prevent sanding through the top coat layer, it is necessary to optimise the application process by means of the application technology and the paint setting so that patterns in the top coat that require levelling off during intermediate sanding are kept to a minimum.

-

If the painted surfaces are uniform (no patterns), the doors can be processed in the following way when sanding:

- Connect the eccentric sander to a mobile dust extractor.

- Affix GRANAT P400 sandpaper to the sanding pad of the eccentric sander and sand the doors evenly without applying pressure.

- Sand the rebate areas evenly with the manual abrasive without using the tool.

- Once the dust has been removed from the surfaces, the final coating process can begin.

-

Our illustrated guides and work results are documented working steps that we have performed in practice. They are individual examples and do not guarantee or promise that users will obtain the same results. The results will depend on the user's experience and skill, as well as the material being used. Illustrated guides do not replace any Festool operating manuals and/or safety instructions. Liability for ensuring that the information, instructions and applications are free from content defects and defects of title, in particular with regard to the absence of defects, correctness, freedom from third party intellectual property rights and copyrights, completeness and fitness for purpose, is excluded. Claims for damages made by the user, regardless of their legal basis, are excluded. These liability exclusions are not applicable if the damage was intentional or caused by gross negligence, or in cases of statutory liability.

We cannot accept liability for damage resulting from defects.↑